For the last two years, I purchased Thistle/Nyjer seed feeders, like the one above. Made of fabric, the goldfinch rip them apart getting out the seeds. They didn't last more than one season.

For the last two years, I purchased Thistle/Nyjer seed feeders, like the one above. Made of fabric, the goldfinch rip them apart getting out the seeds. They didn't last more than one season. I tried to make replacement feeders from some fiberglass screening material I had in the garage. As you can see in the photo on the right, the goldfinch ripped open some sizable holes in the fiberglass. Unlike the sock fabric, the fiberglass material didn't stretch. Many a seed found its way to the ground, wasted.

I found quite a few products available online. There are feeders that range from two perches to thirty perches. There are feeders that even have feeding holes under the perches. Seems the goldfinches are the only bird that will feed upside down. So I printed out some images of the feeders and scaled the distance from the perch to the feeding holes and the length of the perches. What I figured was the perches were spaced every 4"/101.6 cm with the feeding holes 2"/58 mm above each 1.25"/31.75mm perch.

Knowing I would be blogging about making the feeder, I sat down one night and wrote down the materials and tools I thought I needed to complete the feeder. Here are my lists:

TOOLS

- Marker

- Measuring device(s)

- Scissors

- Power drill

- 3/16"/5mm drill bit

- 1/8"/3mm drill bit

- pliers with wire cutter

MATERIALS

- 1L Soft drink bottle

- Adhesive tape

- 3/16"/5mm wooden dowel

- Paper for layout

- Heavy wire

- Light wire

- Gather all the tools and materials

- Clear a working surface

- Wash interior of soft drink bottle

- Remove bottle label

- Measure bottle height

- Cut paper

- Fold paper

- Mark holes on paper

- Arrange paper around bottle

- Tape paper to itself and bottle

- Drill 3/16"/5mm holes for dowels

- Drill 1/8"/3mm feeding holes

- Assemble heavy wire ring with eyes

- Attach light wires to heavy ring

- Make hanging bale of heavy wire

- Attach bale through eyes

- Dry bottle before filling with Nyjer seeds

- Clean drill filings from dry bottle

- Fill feeder with seeds

- Screw cap onto bottle

- Hang feeder outside

- Clean up the work area

I will go over step by step my procedures to create the feeder from scratch.

Here are the materials and most of the tools.

I first measured the height of the bottle from the table top to where the bottle begins to reduce in circumference. I decided 7"/ 178.8mm was good.

I measured 7"/178.8mm from a factory cut edge toward the center of the paper and placed a mark in four places along the length of the paper. I was using packing paper that was inside a recent mail order shipment. That is why the paper is wrinkled.

Next, rather than using a straight edge/yardstick, I folded the paper using the marks and factory cut edges on the ends to create a straight line. I tried to keep the fold straight but measured the paper along the fold to be sure I was close. It isn't necessary to have a perfectly straight line. That edge will be the top of the bottle and this isn't even bottle rocket science.

Cut along that fold (with the scissors I forgot to photograph).

You will now have a long length of paper that is 7"/178.8mm tall. Roll the paper around the bottle, keeping the paper tight against the bottle. Mark the paper where the factory edge touches the main body of the paper.

This is the length of the paper needed to cover the circumference of the bottle. I figured 10-5/16"/26.19375cm. I cut the length longer and folded the paper to length. I did this to add some substance to the paper, make it less likely to tear. You can see I marked the factory edges, so I wouldn't forget.

I decided the night before to have perches every 90º. Now I to layout the holes on the paper. At this point I could have gone to the garage for my rafter square. Marking the holes on the paper would be tedious, to say the least. Instead, I folded the paper widthwise in quarters, because there are four 90º arcs in a circle.

First fold the paper in half widthwise.

Open the paper to full width. Fold each end into the center crease.

Then do the same for the other end.

You now have four equal vertical divisions. Now for the horizontal divisions.

Remember, I wanted to place the perches 2"/50mm from each feeding hole. I decided to place a perch 1/4"/6.35mm from the bottom of the bottle. Then the first feeding hole would be 2"/50mm above that. There would be another perch at that level rotating 90º around the bottle. I marked the paper 1/4"/25mm up from the bottom factory edge. Then 2"/50mm up from that. Then another mark 2"/50mm up from that mark and another 2"/50mm to another mark.

I then folded the paper at each of those marks making sure the vertical folds aligned which keeps the horizontal lines straight.

What results is a grid of folded creases with the first horizontal crease 1/4"/ 6mm above the bottom edge.

I then marked on the paper each hole to be drilled. The circled crease intersections are for perches the others for feeding holes.

I removed the label at this point. It can be removed at any time before you cover the bottle with the layer of paper. I used a utility knife. Lift the label a bit and cut under the label. Do not cut the bottle, or your fingers, hand or any part that may bleed, please.

There were two strips of label remaining after peeling the label. I placed the bottle under running hot tap water to remove the remaining label. There was some adhesive residue left on the bottle. I didn't think removing the residue was important.

The next step is to align the paper with the bottom of the bottle. I wanted to place a perch 1/4" 12mm from the bottom. This proved difficult. There are five divisions on the bottle bottom, every 72º. My layout for perches are at 90º. The holes would need to be at the edges of divisions and just glancing the walls of the divisions. I gave up on the bottom perches.

Tear off some strips of adhesive tape. Place them half on the work surface with the other half over the edge in mid-air so you will be able to grab it easily with one hand. Stand the bottle on its bottom. Wrap the paper around the bottle, keeping it as tight as possible. Align the lines and place one piece of tape on the seam to keep the paper in place.

Making sure the bottom edge of the paper is touching the work surface, place tape strips along the seam. Then tape the top of the paper to the bottle. The bottle is ready to drill. As you see in the photo above the perch holes are circled.

Put the 3/16"/5mm drill bit into the power drill. (I thought about using a hot nail to make the holes but, I was afraid using heat might result in holes larger than needed.) Don't push hard. The bottle wall will collapse. You will need to squeeze the bottle to add rigidity. The bit may slide off the mark. Be patient. Whatever you do, do not place your holding hand directly across from the hole being drilled. Ventilated hands are not in fashion this spring. Nor is the color, blood red. Once all the larger perch holes are drilled, change to the smaller bit to drill the feeder holes.

With all the holes drilled, it is time to cut the wooden dowel. The bottle is approximately 3"/75mm in diameter. The perches need to project at least 1"/25mm from the bottle wall. I decided to cut the dowels at 5-1/2"/14cm.

Since the dowel has such a small diameter, I used the utility knife to cut it. Again, be careful. Use a gentle pressure and roll the dowel on the table to mark the cut. Then begin to increase the pressure while rotating the dowel, bit by bit. Be sure the work surface is sturdy and able to take the pressure you will be exerting to make the cut. If you are using the kitchen, dining room or coffee table, use a cutting board under the dowel. Your spouse will appreciate it.

Insert the dowels into the perch holes. The holes should be snug. The bottle will need to be squeezed a bit to get the dowels through. Leave equal amounts of dowel projecting from each side of the bottle. If the holes are snug you will not need to water proof or place any caulk around the dowels. If the holes are loose, silicone caulk may be used to keep the dowels in place. Use as little caulk as possible.

Next step is the hanging structure, starting with the hanging ring.

The circumference is 10-5/16"/ 26.19375cm. Use wire cutters or pliers with a wire cutting edge to cut a length of heavy wire about 1/3 longer than the circumference. Bend the wire in half and twist an eye at the center of the wire. I twisted the wire around a 20 penny common nail to keep the eye open and round. The next step might take some trial and error. You need to make an eye half the circumference from the first eye and still have it 180º around the bottle. Then wrap the wire into a ring.

Fit the loop around the bottle. You can adjust the spacing of the eyes and the tightness of the ring. The ring doesn't need to be perfect. Close is good. The light wire will hold the bottle in place.

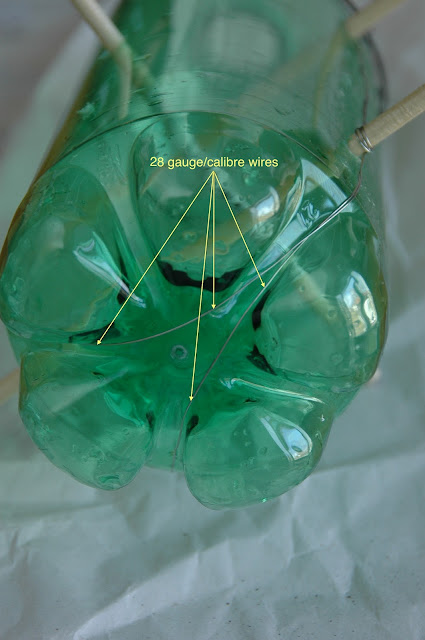

Cut two 24"/ 61cm lengths of light wire. Wrap one end of the wire over the heavy wire and twist the wire to itself. Then run the light wire under the bottom of the bottle into one of the and back up the other side and over the hanging ring and fasten it to itself.

Do the same with the other cut wire using the same indentation on one side of the bottle but use a different indentation 72º from the original path taken by the first wire. Attach it also to the hanging ring. In order to keep the wires from sliding around the bottle place them on both sides of the perches.

Cut a length of heavy wire approximately 12"/30cm long. Bend 1"/25mm 180º on each end in opposite directions. Create a gentle bend in the wire to make a hanging bale. Place one bent end into each eye on the hanging ring and bend them so the bottle won't fall off. Remove any drill filings from the bottle. The bottle is ready to be filled.

Using a funnel, fill the bottle with seeds.

Go slowly. Don't make a mess.

You will notice that because I didn't drill the holes close to the bottom of the bottle, there are two holes that don't have perches. I am hoping the Goldfinch will hang upside down to feed from the holes below the perches.

I had to adjust the hanging bale a bit to get it to hang plumb. Not a big problem. I encircled the time lapse camera on my breakfast room window to give you some reference.

This is a reference photo to the other feeder.

There very next day the first Goldfinch was at the feeder.

It won't be long the hummingbirds return.

Have you made reservations for your summer vacation?

©Damyon T. Verbo - all rights reserved